- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

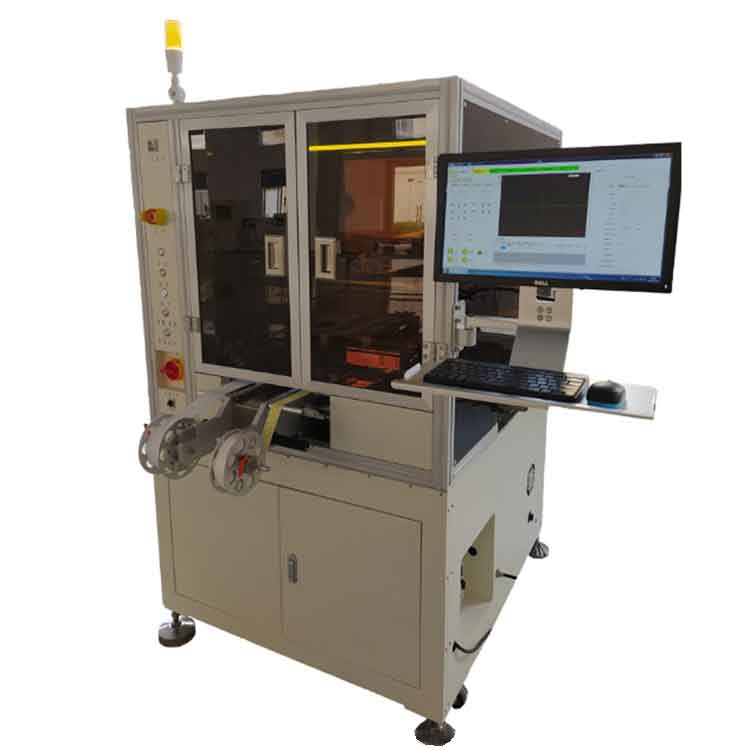

High-speed SMT Labelling Machines

- Product:High-speed SMT Labelling Machines

- Catalogue:Labelling machines

- Views:178398times

- Update:2018/8/31 11:36:34

- Call:133-6065-4218

High speed SMT labelling machine configuration

Two placement heads.

Two Feeder

High-speed SMT labelling machine function

High speed SMT labelling machine is suitable for SMT industry for all kinds of circuit boards that need labeling, backing and stickers

High speed SMT labelling machine to improve SMT line labelling machine capacity

High-speed SMT labelling machine significantly reduces operator error rate in labelling

High-speed SMT labelling machine makes the SMT production line more smooth and efficient. After labeling, the label information can be scanned

and read realistically and docked with the MES system for feedback.

| Structure | Number | Structure |

| Product placement and transfer rails | 1 set | The carrier mounting X-axis motion module and the orbital belt transfer mechanism ensure fast and smooth movement and mounting. |

| XY Drive Modules | 1 set | The XY drive mechanism uses linear motors to ensure speed and efficiency of placement |

| Fiducial Components | 1 set | The feeding mechanism is designed and processed by our own research and development, using high-precision stepper motors and highly sensitive fibre-optic sensors to ensure stable material discharge. |

| Adhesive Backing Mechanism | 1 set | The adhesive backing assembly uses high speed, high precision precision linear motor + double actuator, Z-axis is driven by servo motor + our own design high precision nozzle rod module, 0-360° R-axis rotation servo motor; high performance vacuum generator and negative pressure sensor to ensure the stability of the suction material. Two quick release nozzles |

| Vision systems | 2 set | The vision system includes 1 set of CCD vision for the top camera and 1 set of CCD vision for the bottom protective film. The CCD camera adopts the German Yingmeijing brand products with gigabit network card to transmit data, the high precision CCD camera provides high precision visual alignment for the whole machine combined with the company's own knowledge of product software system to ensure high precision placement. |

| Motion control systems | 1 set | The use of industrial grade PC and Lacey motion control cards for the control of the whole machine combined with our own control software ensures efficient and stable operation of the equipment, and can also be customised according to customer requirements. |

| Electronic control system | 1 set | Motion controls, relays, servo controls, air switches, short-circuit switches, regulated power supplies, etc. are installed inside the machine, saving space and ensuring safety and reliability. |

| Frame + large board | 1 set | Contains the main frame and a set of large plates, welded to a high standard with thickened square passages. |