- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

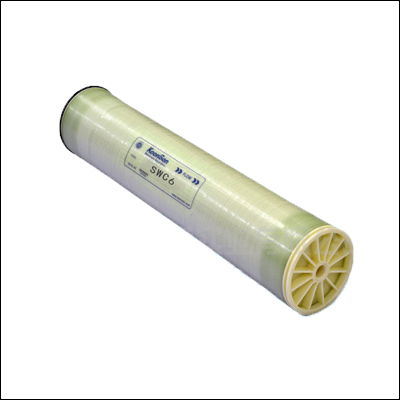

SWC6 desalination film

- Product:SWC6 desalination film

- Catalogue:Adhesive backing machine

- Views:178253times

- Update:2019/8/13 17:39:57

- Call:133-6065-4218

With the world facing a shortage of fresh water, head can bring a series of SWC desalination membranes to meet the needs of the desalination industry. SWC membrane has been improving water production capacity and desalination rate for more than 20 years, while reducing the impact on the environment. The SWC membrane USES different innovative formulas according to the salt content of seawater.

SWC seawater desalination film has outstanding water production capacity and desalination rate in the industry, combining with optimized water volume, anti-pollution and low energy consumption technologies to meet different needs of customers.

SWC seawater desalination membrane can not only be used for desalination system with seawater as water source, but also for the treatment of industrial wastewater with high TDS. In the selection and design of membrane elements, traditional or mixed installation can be adopted.

SWC6 is the most energy efficient model in Hyde energy desalination membrane series. When sea temperatures are low, systems using SWC6 require lower pressure, saving operating costs. The SWC6 diaphragm can be rolled into two 8 "membrane elements

When using traditional pretreatment, LD technology ® can reduce colloid pollution, slow down the rise of pressure difference, and prolong the cleaning cycle.

The membrane area of the MAX membrane element is 440 ft2 (40.9 m2), which can save about 10% membrane quantity when using the same water flux design.

I. performance parameters of SWC6 Hyde energy desalination RO membrane:

|

model

|

SWC6 |

|||

|

specifications

|

8 inches

|

|||

|

performance

|

Desalination rate

|

/ |

Low pressure |

High yield and water |

|

nominal

|

99.6% |

99.8% |

||

|

The minimum

|

99.4% |

99.7% |

||

|

Water rate

|

6000 gpd (22.7m3/d) |

12000gpd (45.4m3/d) |

||

|

type

|

Film material

|

Aromatic polyamide composites

|

||

|

structure

|

Roll type |

|||

|

Feed water screen thickness

|

400ft²(37.2㎡) |

|||

|

Test condition

|

solution

|

32000mg/L NaCl |

||

|

pressure

|

600psi(4.1Pa) |

800psi (5.5MPa) |

||

|

The temperature

|

77°F(25℃) |

|||

|

The recovery rate of

|

10% |

|||

|

pH |

6.5-7.0 |

|||

* the performance parameters are obtained after the system runs steadily for 30 minutes. The actual test conditions may not be exactly the same as the above data, in which case the performance parameters are standardized data based on standard conditions. The deviation range of water yield is within -- -15-151515 --+25 +25+ 25% %%%.

Ii. Use and restriction of products

Maximum operating pressure

600 psig (4.14MPa)

The largest water residual chlorine concentration

<0.1 mg/L

Maximum inlet temperature

113 °F (45 °C)

Operating pH range

1-12(25℃,30 分钟)

Maximum inlet turbidity

1.0 NTU

The largest water SDI15

5.0

Maximum inflow

85gpm (19.3mm³/h)

The high salinity water flux of the lowest

12gpm ( 2.7m3/h)

Maximum pressure drop for single membrane elements

10psi (0.07MPa)

This is only a general constraint. For specific projects, more conservative operating parameters can ensure better performance and longer service life. For details, please refer to the relevant technical data of Hyde energy.

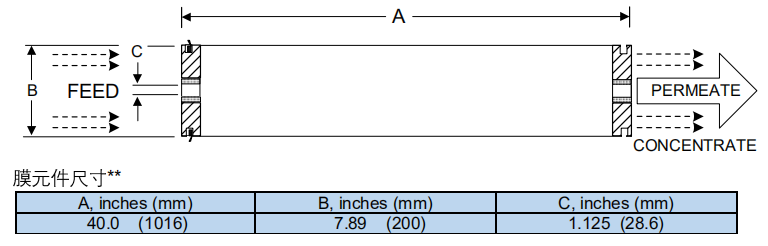

Iii. Product description

Disclaimer: the information and data provided herein are in good faith and in lieu of any warranty. All warranties, express or implied, including warranties of merchantability and fitness for a particular purpose, are hereby denied and excluded. The conditions and methods of use of our products are beyond our control. Hyde energy shall not be liable for the results or damages resulting from the use of this information and data. It is the responsibility of the user to determine the suitability of heidner's products for their particular use.