- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

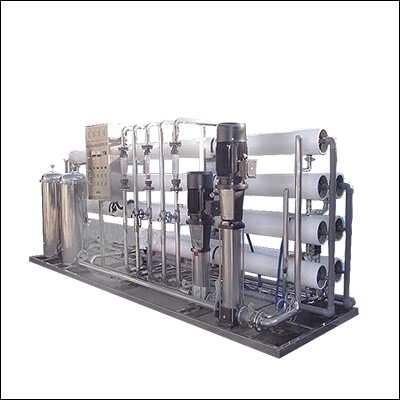

First-stage reverse osmosis water treatment equipment

- Product:First-stage reverse osmosis water treatment equipment

- Catalogue:Labelling machines

- Views:177657times

- Update:2018/8/31 14:01:44

- Call:133-6065-4218

Equipment specification:

Single-stage reverse osmosis equipment, also known as first-stage reverse osmosis equipment, is composed of pre-treatment system, pre-treatment system, host system and post-treatment system. The device consists of raw water tank, raw water pump, multi-medium filter, activated carbon filter, water softener, precision filter, RO system, ultraviolet sterilizer and so on. Single-stage reverse osmosis equipment will be affected by many factors during operation, which may cause some problems. The main countermeasures can be short-term or long-term shutdown and maintenance. Short-term shutdown maintenance can be protected by low-pressure flushing every 1 ~ 3d, while long-term shutdown maintenance can be protected by low-pressure flushing every 2d or 1d.

The process flow:

Original water tank → raw water booster pump → quartz sand filter → activated carbon filter → scale inhibitor feeding equipment → precision filter → first-stage high-pressure pump → first-stage reverse osmosis system → pure water tank → water supply pump → ultraviolet sterilizer → rear filter → water point

1. Raw water tank: it stores raw water of the system, plays a regulating role in the water inflow, and also plays a certain role in precipitation of impurities in the water inflow.

2, raw water pump: constant system water supply pressure, stable water supply.

3, multi-media filter: the main purpose of the filter is to remove sediment, rust, colloidal substances, suspended substances and other substances with particles above 20um from the raw water, so as to reduce the turbidity of water, ensure the water quality of the equipment and extend the service life of the equipment. The system can carry on a series of operations such as backwashing and forward washing.

4. Activated carbon filter: remove pigment, peculiar smell, large amount of biochemical organic compounds in water, reduce residual chlorine value of water and pesticide pollutants, and remove trihalide (THM) and other pollutants in water. The system can carry out a series of operations, such as backwashing, backwashing, and so on.

5, soften system: to prevent the thick water side especially RO device last membrane module thick water side of CACO3, MGCO3, MGSO4, CASO4, BASO4, SRSO4, SISO4 concentration is greater than the equilibrium solubility constant crystallization and precipitation, membrane damage shall have the characteristics of the original, before entering the reverse osmosis membrane module system USES type cation exchange resin, sodium ion exchange adsorption, remove the water hardness ingredient, after adsorption saturation, resin, industrial salt for regeneration of resin are available, and to restore the exchange capacity. Each softening system includes: softening tank, controller (or jet/salt pump), salt box and salt valve.

Main functions: prevent reverse osmosis from scaling and extend the service life of reverse osmosis membrane

6. Scale inhibitor dosing system: in order to prevent CaCO3, MgCO3, MgSO4, CaSO4, BaSO4, SrSO4 and SiSO4 from crystallizing on the concentrated water side of the last membrane component of RO device, especially the concentrated water side of the last membrane component of RO device, and to damage the proper characteristics of the film original, a scale inhibitor dosing system is configured before entering the reverse osmosis membrane component. System includes: dosing pump, dosing box, water level switch.

Main function: prevent reverse osmosis membrane from scaling, extend the service life of reverse osmosis membrane.

7. Security filter/precision filter: used to intercept a small amount of mechanical impurities leaked by the pretreatment system. Filter cylinder adopts engineering plastic or SUS304 material; Built-in PPF filter element. Polypropylene filter element is a deep filter element with high efficiency and low resistance. It is suitable for further purification of water with low suspended impurities (turbidity less than 2-5 degrees). The polypropylene filter element is formed by winding polypropylene fiber on the porous injection polypropylene tube according to a certain rule.

Main functions: ensure that the particle size of water entering the reverse osmosis membrane is less than 0.1um. Prevent large particle impurities from entering the reverse osmosis membrane, causing damage to the membrane, protect the reverse osmosis membrane.

High pressure pump

Because reverse osmosis membrane needs high pressure in the working process, high-pressure pump is the main operating equipment of reverse osmosis system, providing power source for reverse osmosis device. This system USES multistage vertical centrifugal pump, the material is SUS304, has the appearance beautiful, the area is small, the noise is small, the maintenance is free, durable characteristic.

The inlet of high-pressure pump is protected by low-voltage protection switch. When the inlet pressure is lower than the set value (0.05mpa), stop the high-pressure pump to prevent the damage of the high-pressure pump.

The inlet of high-pressure pump is protected by high-pressure protection switch. When the inlet pressure is higher than the set value (2.0mpa), stop the high-pressure pump to protect the high-pressure pump and membrane components from damage.

Reverse osmosis system

Reverse osmosis (RO) is to only allow the choice of water molecules through the reverse osmosis membrane intercept, under the pressure of osmotic pressure above the solution, the water molecules through the membrane continuously, and less than the reverse osmosis membrane aperture of heavy metal ions, organic matters, such as bacteria, viruses, interception on the inlet side of the membrane, so as to achieve the separation purification purposes. The whole working principle adopts physical method, without adding any fungicides and chemical substances, so there will be no chemical variation

10. Pure water tank: store reverse osmosis water and provide water source for water points.

Equipment advantages:

· reverse osmosis is to desalinate and purify saline by a physical method without phase change at room temperature. At present, the desalination rate of ultra-thin composite film elements can reach more than 99.9%, and at the same time can remove the colloid, organic matter, bacteria, viruses, etc.

· water treatment only relies on water pressure as the driving force, and its energy consumption is the lowest among many water treatment methods;

· reverse osmosis can continuously operate the water system, with simple system, convenient operation and stable product water quality;

· no discharge of chemical waste liquid, waste acid and alkali, no neutralization process of waste acid and alkali, no environmental pollution;

· the reverse osmosis device has a high degree of automation, and the workload of operation maintenance and equipment maintenance is very small;

· the equipment occupies less space and requires less space;

· good removal effect of silica in water, with removal rate up to 99.5%;

· remove colloidal substances such as organic compounds in water, the removal rate can reach 99.5%;

· reverse osmosis water treatment system can continuously produce water without stopping regeneration and other operations;

· suitable for both brackish water and seawater treatment and fresh water treatment with low salt content.

Application field:

· ultra-pure water treatment for electronics, semiconductor, printed circuit board and integrated circuit, precision machinery manufacturing and other industries

· process pure water treatment for fine chemical industry, precision science, cosmetics manufacturing and other industries

· sanitary grade pure water treatment in food and beverage industries

· purified water treatment in pharmaceutical, medical and life science industries

· wastewater treatment in metallurgy, light industry, electroplating and leather industries

· softened water and desalinated pure water treatment for boiler feed water

· desalination of seawater and brackish water