- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

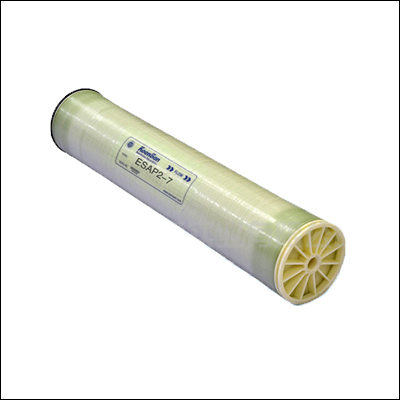

Ultrafitration membrane module

- Product:Ultrafitration membrane module

- Catalogue:Adhesive backing machine

- Views:178342times

- Update:2013/3/26 15:40:00

- Call:133-6065-4218

Ultrafiltration (UF) works:

Ultrafiltration technology in recent years, relying on materials science to develop the advanced membrane separation technology, has been widely applied to industrial and municipal construction in various fields.

Ultrafiltration (UF) is a pressure-driven membrane separation process, which uses porous materials ability to intercept, the particulate matter from the fluid and dissolved components separated. The typical membrane pore size in the 0.01-0.1 micron range, for bacteria and most viruses, colloids, silt has a high removal rate. The smaller the nominal pore size membrane, the removal rate is higher. Ultrafiltration membranes are commonly used polymer materials, the basic nature of the hydrophobic in nature. Able to blend other hydrophilic modification. The process for the room temperature operation, no phase change, and no secondary pollution.

Ultrafiltration using polyvinylidene fluoride (PVDF) material, the Department of dual hollow fiber structure of the cortex. In the industrial applications of PVDF membrane, the ultrafiltration with the smallest nominal pore size, can remove almost all particles, bacteria (4-log removal), most viruses and colloids. Although the pore size is small, but its high porosity makes the ultrafiltration and microfiltration to obtain considerable flux, which in most cases is a better choice than MF.

UF used to plug the external pressure is not easy to structure, with a higher amount of pollutant, the greater the filtration area, and easier to clean thoroughly. Flow pattern-based design to full-flow filter, but the components can be easily converted into a cross-flow filtration mode. Compared with cross-flow, full flow filtration and low consumption, low operating pressure, and thus lower operating costs. In contrast, cross-flow filtration of suspended solids is able to handle more fluid. Therefore, according to the specific needs of the operation in the form of suspended solids in water content to determine.

Usually constant ultrafiltration run, transmembrane pressure (TMP) will gradually increase over the execution time, this time through regular backwashing or air pollution can be cleared scrub layer, the use of fungicides or other cleaning agents are able to more thoroughly control of microbial removal of contaminants.

In the field of water treatment, ultrafiltration can be used out of the water particles, colloids, bacteria, viruses, heat, protein and organic polymer, the water to be purified.

Advantages and characteristics of ultrafiltration

* Long life: the performance of PVDF ultrafiltration using special hydrophilic material and have been modified, has excellent antioxidant and anti-fatigue, anti-pollution, anti-clear, greatly extending the life of the film wire.

* High quality water production: the average ultrafiltration filter accuracy 0.03μm, bubble point pressure higher removal rate of bacterial 6-log, making it better capacity water quality.

* Wide range of applications: ultrafiltration of the external pressure structure and patented water distribution means, to allow a wider water suspended solids content, more suitable for the application of poor water quality conditions, while ensuring a high water recovery.

* Low operating costs: UF external pressure can be low-cost way to clean air and water mix, and efficient long-term stability to maintain throughput, saving chemical cleaning agent consumption.

|

Products |

SFP Series |

|||

|

Application |

Pre-industrial water supply |

Waste water reuse |

Drinking water treatment |

|

|

Model |

SFP-2640 |

SFP-2860 S |

SFP-2660 |

|

|

SFP-2660 |

FP-2880 |

SFP-2860 |

||

|

SFP-2680 |

|

SFP-2880 |

||

|

Size |

Length (mm) |

1356, 1856, 2356 |

1860, 2360 |

1856, 1860, 2360 |

|

OD (mm) |

165, 165, 165 |

225, 225 |

165, 225, 225 |

|

|

Area(m2) |

20, 33, 44 |

52, 70 |

33, 52, 70 |

|

|

Basic parameters |

Forms(Outside-In flow) |

hollow fibers |

hollow fibers |

hollow fibers |

|

Basic Polymeric |

PVDF |

PVDF |

PVDF |

|

|

nominal pore diameter (μm) |

0.03 |

0.03 |

0.03 |

|

|

outside diamete(mm) |

1.3 |

1.3 |

1.3 |

|

|

Flux(lmh) |

50-120 |

40-100 |

60-120 |

|

|

pH Range |

2-11 |

2-11 |

2-11 |

|

|

Temperature ℃ |

1-40 |

1-40 |

1-40 |

|

|

Feed Pressure (bar) |

6 |

6 |

6 |

|

|

NaOCl, Cleaning Maximum(ppm) |

5,000 |

5,000 |

5,000 |

|

|

Typical process conditions |

Operating TMP(bar) |

2.1 |

2.1 |

2.1 |

|

TSS (ppm) |

100 |

150 |

100 |

|

|

Particle Size(μm) |

50 |

50 |

50 |

|

|

Journal of the largest fiber (ppm) |

300 |

300 |

300 |

|

|

typical fiber journal(ppm) |

5 |

5 |

5 |

|

|

Max.Feed Backwash (bar) |

2.5 |

2.5 |

2.5 |

|

|

Backwash Flux(lmh) |

100-200 |

100-200 |

100-200 |

|

|

Backwash Cycle Time |

15-60 min |

15-60 min |

15-60 min |

|

|

one time |

one time |

one time |

||

|

Backwash Time(sec) |

30-60 |

30-60 |

30-60 |

|

|

typical chemical cleaning cycle |

4-12 time/year |

4-12 time/year |

4-12 time/year |

|

|

Air wash Cycle time |

1-12 time/day |

1-12 time/day |

1-12 time/day |

|

Drinking water equipment:

Water shortages, exacerbated by the status of surface water pollution threat to human drinking water source. SFP Series ultrafiltration products, high filtration precision of the water of suspended solids, colloidal impurities, in particular, removal of Cryptosporidium, Giardia, E. coli and other pathogenic microorganisms has a very high removal efficiency. By relevant state departments of health inspection for the safety of your drinking water to provide the most economical and reliable protection

RO Pretreatment:

Ultrafiltration to reverse osmosis system to provide a more stable, better quality water water, reverse osmosis membrane to maximize the protection from pollution and congestion, greatly extending the life of reverse osmosis systems. SFP Series Ultrafiltration products in China's electric power, petrochemical, petroleum, electronics and other fields of reverse osmosis pretreatment system is widely used, the processing in quantities greater than 600,000 tons of market share ahead.

Industrial wastewater, municipal wastewater reuse:

Ultrafiltration to remove industrial waste and municipal waste water of suspended solids, colloids, organic matter and other impurities, in order to achieve the depth of wastewater and sewage treatment and reuse of available pre-security. SFP Series ultrafiltration products, 8-inch diameter, large pollutant components, wire withstand tough PVDF membrane more frequent water, gas and chemical cleaning.

Water filtration:

Ultrafiltration excellent performance to completely replace the coagulation, sedimentation and filtration of the traditional multi-media approach. Multiple reverse osmosis desalination system at home and abroad, in order to provide high-quality reverse osmosis desalination, water stable, set a model for sea water applications.

Currently, more and more SFP ultrafiltration device has been put into operation in China, in power, steel, petrochemical and other industries of industrial water-saving and environmental protection areas, are playing an increasingly important role.