- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

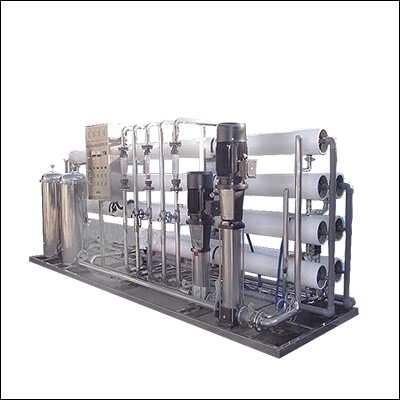

Pharmaceutical plant purified water treatment equipment

- Product:Pharmaceutical plant purified water treatment equipment

- Catalogue:Labelling machines

- Views:178330times

- Update:2018/8/31 15:20:21

- Call:133-6065-4218

According to the regulations of the Chinese Medicine Bureau, the purified water equipment for medical use is divided into two standards:

One is medical purified water and the other is water for injection.

These two are completely different standards. The water for injection is a standard for the filtration and extraction of water treatment equipment on the basis of medical purified water. Generally, the purified water in medical plants is double. Reverse osmosis water treatment equipment, while water for injection must use a distillation process, usually using a multi-effect distiller to make water. The water for injection is mostly prepared on the basis of medical purified water, which can save cost and ensure water quality. We usually use both purified water and water for injection in one place.

Through the detection of TOC at different water intake points, we can analyze whether our water treatment equipment is the filter element, whether it is replaced or whether the pipeline is cleaned. In the inspection of hospital-related water treatment equipment, there are also projects for detecting TOC.

Medical water is not only the requirement of our water treatment equipment, but also has strict requirements on the pipeline. Only the pipeline design is reasonable, can effectively avoid the breeding of bacteria again, and ensure the water quality is stable and qualified.

Purified water should be transported in loop loops. The piping design should be simple, and blind tubes and dead ends should be avoided. Pipes shall be made of stainless steel pipes or other pipes that have been verified to be non-toxic, corrosion-resistant and do not bleed out contaminated ions. The valve should be a hygienic valve with no dead angle, and the purified water should be marked with flow direction.

Swimming pool water treatment equipment overview:

With the rise of swimming pools around the world, swimming pool water treatment equipment has gradually gained more use. It can effectively solve problems in the operation and maintenance of swimming pools, and the economic benefits are considerable.

Swimming pool water treatment equipment parameters:

Raw water: tap water, well water, ground water, medium water;

Inlet water pressure: 0.2~0.3MPa;

Operating pressure: 0.3~1.5MPa;

Desalination rate: >99%;

Control: automatic control / manual automatic switching;

Water production: 0.25~200T/H (according to customer needs);

Material: PVC/304/316L/FPR;

Process: reverse osmosis membrane separation technology;

Water conductivity: <10 μs/cm, 5 μs/cm, 2 μs/cm, and the like.

Advantages of swimming pool water treatment equipment:

1. Large filtration area;

2. The equipment has a small footprint;

3. High water production rate, good water quality and stable operation;

4. Easy to disassemble and easy to install, easy to overhaul, good anti-flushing effect and short time.