- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

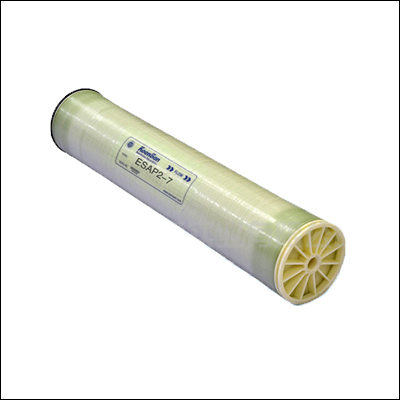

American heideren PROC series anti-pollution film

- Product:American heideren PROC series anti-pollution film

- Catalogue:Adhesive backing machine

- Views:178400times

- Update:2013/3/26 15:39:57

- Call:133-6065-4218

PROC10 Hydranautics membrane is March 2006, the company recently introduced a series of products, but also the United States Hydranautics PROCTM (Powerful Reverse Osmosis Composite) enhanced series of the first products. This product is in the following two aspects of the development and improvement: flat membrane structure technology: the use of advanced polymer synthesis technology to improve the surface layer of flat membrane density to achieve the world's highest rate of low-voltage reverse osmosis desalination membrane. Membrane structure improvements: First, use the special structure of the water across the network to achieve low dropout, low fouling, easy cleaning purposes; second end plate at the cut-flow (ATD) additional exhaust constructed to ease the system starts when the impact of the membrane, reducing membrane breakage rate.

Using the above techniques improve, making PROC10 not only have better water quality and superior product performance, pollution prevention, while also reducing the possibility of failure of the membrane system.

As PROC10 water production, anti-pollution and chemical cleaning performance superior to other film companies have similar products, making PROC10 was quickly recognized by customers in China, since May 2006 Henan Xinxiang Chemical Fiber Group Co., Ltd. Egret become PROC10 in China since the first users, in less than a year's time period, there were already more than 10 000 8 in. membrane into use in industrial systems.

PROC20 birth, thanks to the company for many years in the ultra-low pressure reverse osmosis composite membrane of continuous exploration. Finally achieve energy-saving and high rejection rate, high resistance to pollution, the perfect combination of performance. The reverse osmosis system using PROC20 the same design conditions, the tons of water and electricity consumption compared to other anti-pollution products may be reduced by 30%, to maximize energy savings, reducing the cost of water. Meanwhile, the membrane with anti-pollution features, so as to maintain a pollution-resistant, easy to clean, low pressure drop characteristics.

Technical parameters:

|

Type

|

Model

|

PROC10

|

PROC20

|

|

|

Type

|

Size

|

8 inch

|

||

|

Membrane Polymer

|

Composite Polyamide

|

|||

|

Membrane Active Area

|

ft2

|

400

|

||

|

㎡

|

37.2

|

|||

|

thickness of the water network , mil

|

34

|

|||

|

Performance

|

Salt Rejection, %

|

average

|

99.75

|

99.5

|

|

Min

|

99.6

|

99.2

|

||

|

Permeate Flow

|

gpd

|

10500

|

||

|

m3/d

|

39.7

|

|||

|

Test Condition

|

NaCl , mg/l

|

2000

|

||

|

Pressure,psi(MPa)

|

225(1.55)

|

150(1.05)

|

||

|

Temperature,℃

|

25

|

|||

|

Permeate Recovery,%

|

15

|

|||

|

Test fluid pH

|

6.5-7.0

|

|||

|

Application Data

|

Maximum Applied Pressure

psi(MPa) |

600(4.14)

|

||

|

Maximum Feed Flow

gpm ( m3/h) |

90(20)

|

|||

|

Maximum Operating Temperature

℃ |

45

|

|||

|

Feedwater pH Range

|

2-11

|

|||

|

Cleaning pH Range

|

1-13

|

|||

|

Maximum Feedwater Turbidity

NTU |

1.0

|

|||

|

Maximum Feedwater

SDI15 |

<5

|

|||

|

Maximum Chlorine Concentration,

mg/l |

<0.1

|

|||

|

Minimum Ratio of Concentrate to

Permeate Flow for any Element |

5:1

|

|||

|

Maximum Pressure Drop for Each Element

psi(MPa) |

5:1

|

|||