- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

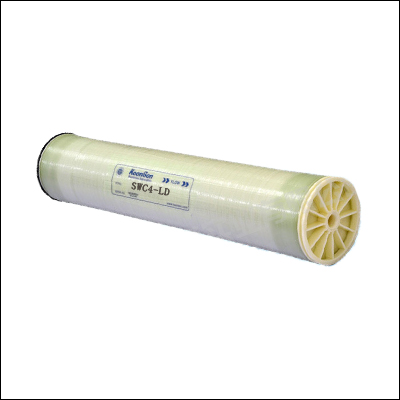

Hyde energy ESNA1 series nanofiltration membrane

- Product:Hyde energy ESNA1 series nanofiltration membrane

- Catalogue:Adhesive backing machine

- Views:177452times

- Update:2013/3/26 15:39:57

- Call:133-6065-4218

Hyde energy ESNA1 series nanofiltration membrane:

U.S. Hydranautics ESNA launched in 1996, energy-efficient nanofiltration membrane can effectively removing hardness, iron, color, and chloroform (THM) and other substances, and at very low pressure can also be obtained through the high water volume. Low-voltage operation not only saves energy, and associated pumps, piping and pressure vessels and other ancillary equipment is also cheaper, ESNA series of membrane modules of the advantages of growing users of all ages.

In 2004, Hydranautics will clean performance nanofiltration membrane technology with the organic combination of the original ESNA1 nanofiltration membrane modules, based on the development of neutral ESNA1-LF and ESNA1-LF2 products . Both nanofiltration water conditions can be complex in some applications a stable operation.

|

ESNA Series Performance parameters |

||||||

|

Model |

ESNA1-K1 |

ESNA1-LF |

ESNA1-LF2 |

ESNA1-4040 |

||

|

Type |

Size |

8 inch |

4 inch |

|||

|

Membrane Polymer |

Composite Polyamide |

|||||

|

Membrane Active Area |

ft2 |

400 |

85 |

|||

|

㎡ |

37.2 |

7.9 |

||||

|

Performance |

Salt Rejection,% |

average |

97 |

89 |

86 |

90 |

|

Min |

92 |

86-95 |

83-90 |

80-97 |

||

|

Permeate Flow |

gpd |

10500 |

8200 |

10500 |

2100 |

|

|

m3/d |

39.7 |

31 |

39.7 |

7.9 |

||

|

Test Condition |

Solution Type |

MgSO4 |

CaCl2 |

NaCl |

||

|

NaCI,mg/L |

500 |

|||||

|

Pessure,psi(MPa) |

80(0.55) |

75(0.52) |

||||

|

Temperature,℃ |

25 |

|||||

|

Permeate Recovery,% |

15 |

|||||

|

Test Fluid pH |

6.5-7.0 |

|||||

|

Application Data |

Maximum Applied Pressure |

600(4.14) |

||||

|

Maximum Feed Flow,gpm(m3/h) |

75(17.0) |

16(3.6) |

||||

|

Maximum Operating Temperature |

45 |

|||||

|

Feedwater pH Range |

3~10 |

2~10 |

3~10 |

|||

|

Cleaning pH Range |

2~12 |

|||||

|

Maximum Feedwater Turbidity |

1 |

|||||

|

Maximum Feedwater SDI15 |

<5.0 |

|||||

|

Maximum Chlorine Concentration |

<0.1 |

|||||

|

Minimum Ratio of Concentrate to |

5:1 |

|||||

|

Maximum Pressure Drop for Each Element psi(MPa) |

10(0.07) |

|||||